How does SLS 3D printing work?

How does SLS 3D printing work?

SLS 3D printing uses a high-powered laser to fuse powdered thermoplastic material together into a desired 3D shape. SLS relies on the principle of “sintering” a material to form a solid mass. Sintering refers to the process of compacting a loose material, such as a plastic powder, by the application of heat or pressure. Sintering does not melt the material, but rather provides just enough energy for the atoms of separate objects to diffuse across the material boundaries.

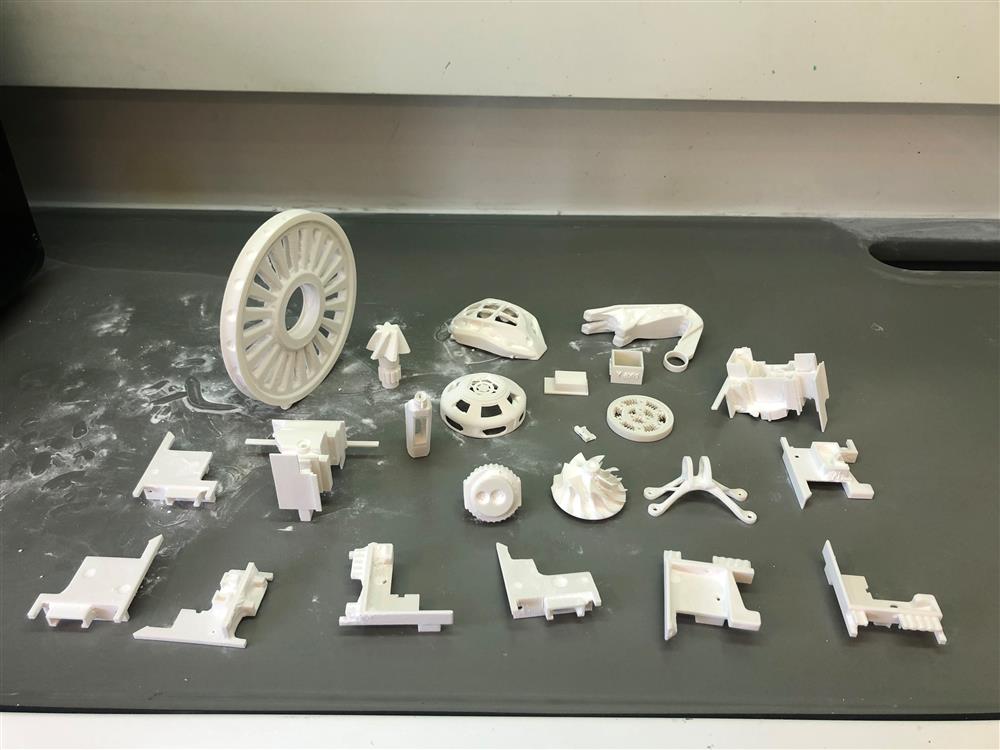

SLS produces tough, functional parts, with the ability to achieve good surface finish, fine detailing and (almost) no geometrical constraints, as it doesn’t need support material.

This production-grade technology is ideal for both functional prototyping and small production runs, as it offers a high degree of design freedom, high accuracy, and exceptional mechanical properties to rival those of injection-molded parts.

ANiMA's choice: https://www.anima.gr/mfgpro-230-xs

Watch the video: https://www.youtube.com/watch?reload=9&v=6Xe5QVbU8Q4&feature=emb_logo