Industrial Production

The iSLM160 Ultimate is an industrial-grade metal 3D Printer, with a large building plate, open materials, and significant printing capabilities. A high-level, affordable solution for small to medium parts.

3D Printing TechnologySelective Laser Melting (SLM)

Beam (diameter@1/e2)0.04~0.15mm

Parts Scanning Speedup to 10.000mm/sec

Build Volume160mm × 160mm x 210mm

The iSLM280 Ultimate is an industrial-grade metal 3D Printer, with a large building plate, open materials and significant printing capabilities. A Value For Money solution for those who want to print large objects.

3D Printing TechnologySelective Laser Melting (SLM)

Beam (diameter@1/e2)0.06~0.20mm

Parts Scanning Speedup to 10.000mm/sec

Build Volume280mm x 280mm x 400mm

Affordable and versatile for low-volume production and fast prototyping, offering quality and accuracy with industrial-grade durability, service, and support.

3D Printing TechnologyFigure 4

Build Volume124.8 x 70.2 x 196 mm

Layer Height10 - 100 microns

Maximum Print SpeedUp to 100mm/hr

Expand your manufacturing capabilities with blue lasers, a large build volume, and a fully inert chamber for the best material properties. Printing is easier due to the improved process control, advanced sensors and live monitoring, allowing you to produce parts consistently 24/7.

3D Printing TechnologyLaser Metal Deposition (LMD)

Build Volume300 x 400 x 600 mm

Material CompatibilityAny commercially available metal in wire

Laser Power1000w

Reliable, open-material, and cost-effective for industrial dental production. iDEN160 Ultimate is a metal 3D Printer with a large building plate and significant printing capabilities to create parts in high accuracy, for precision samples.

3D Printing TechnologySelective Laser Melting (SLM)

Beam (diameter@1/e2)0.04~0.15mm

Parts Scanning Speedup to 10.000mm/sec

Build Volume160mm × 160mm × 130mm - 140mm

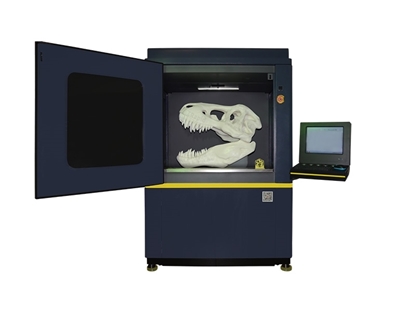

The iSLA1100 Ultimate is an SLA 3D Printer from ZRapid Technologies.

3D Printing TechnologyStereolithography (SLA)

Number of LaserSole Laser

Laser TypeDiode-pumped solid-state laser Nd:YVO₄

Laser Wavelength354.7nm