ZRapid

ANiMA is the official distributor of ZRapid in Europe and provides a wide variety of SLM and SLA 3D printing equipment.

Our expert team will help you find the best solution tailored to your needs!

Email: info@ZRapid.eu

Contact number: +30 210 77 76 822

- 1

- 2

Display

per page

The iSLM160 Ultimate is an industrial-grade metal 3D Printer, with a large building plate, open materials, and significant printing capabilities. A high-level, affordable solution for small to medium parts.

3D Printing TechnologySelective Laser Melting (SLM)

Beam (diameter@1/e2)0.04~0.15mm

Parts Scanning Speedup to 10.000mm/sec

Build Volume160mm × 160mm x 210mm

The iSLM280 Ultimate is an industrial-grade metal 3D Printer, with a large building plate, open materials and significant printing capabilities. A Value For Money solution for those who want to print large objects.

3D Printing TechnologySelective Laser Melting (SLM)

Beam (diameter@1/e2)0.06~0.20mm

Parts Scanning Speedup to 10.000mm/sec

Build Volume280mm x 280mm x 400mm

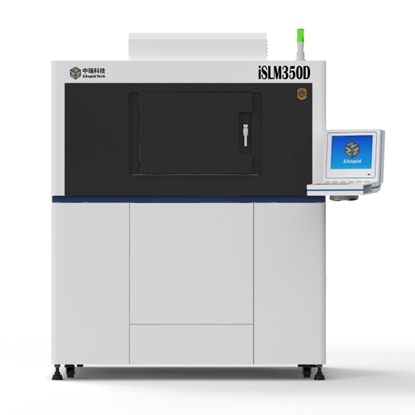

iSLM350D Ultimate is an industrial-grade metal 3D printer that can produce high-quality metal parts with a large build volume. The printer utilizes advanced technologies for gas recirculation and Dual Laser path generation, enabling efficient and cost-effective production of metal parts for various industries, including aerospace, automotive, industrial, and medical.

3D Printing TechnologySelective Laser Melting (SLM)

Beam (diameter@1/e2)0.06~0.20mm

Parts Scanning Speedup to 10.000mm/sec

Build Volume350mm × 350mm x 500mm

iSLM400D Ultimate is an industrial-grade metal 3D Printer. Compatible with a wide range of materials for various applications and significant printing capabilities.

3D Printing TechnologySelective Laser Melting (SLM)

Beam (diameter@1/e2)0.06~0.20mm

Parts Scanning SpeedRecommended 1.0-7.0m/s

Build Volume 400mm x 350mm x 400mm (incl. building platform)

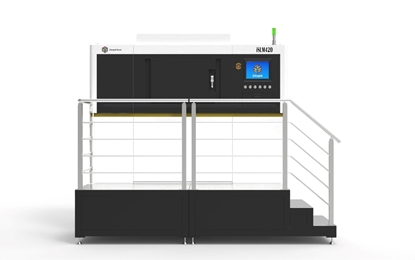

iSLM420 Ultimate is an industrial-grade metal 3D Printer, especially suitable for custom manufacturing of single or small batch functional parts with an extremely large building plate. Compatible with a wide range of materials for various applications and significant printing capabilities. Ideal for those who want to print extremely large, detailed objects with complex geometric shapes.

3D Printing TechnologySelective Laser Melting (SLM)

Beam (diameter@1/e2)0.06~0.20mm

Parts Scanning Speed up to 10.000mm/sec

Build Volume420mm × 420mm x 500mm

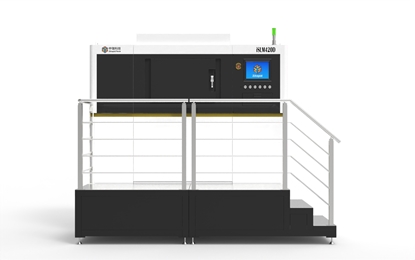

iSLM420D Ultimate is an industrial-grade metal 3D Printer, especially suitable for custom manufacturing of single or small batch functional parts with an extremely large building plate. Compatible with a wide range of materials for various applications and significant printing capabilities. Ideal for those who want to print extremely large, detailed objects with complex geometric shapes.

3D Printing TechnologySelective Laser Melting (SLM)

Beam (diameter@1/e2)0.06~0.20mm

Parts Scanning Speed up to 10.000mm/sec

Build Volume420mm × 420mm x 500mm

The iSLM80P Ultimate is a metal 3D printer designed for applications requiring high precision and detailed geometries. It is engineered to create small, intricate components with precision ranging from 5μm to 25μm. The machine is ideal for industries like electronics, aerospace, energy, and biomedicine, where accuracy and surface quality are critical.

3D Printing TechnologySelective Laser Melting (SLM)

Laser TypeFiber laser

Laser Power100W

Spot Size≈22um

The iSLM600QN Ultimate is an industrial metal 3D Printer equipped with 4 lasers.

3D Printing TechnologySelective Laser Melting (SLM)

Laser TypeFiber laser × 4

Laser Wavelength1064nm

Laser Power4 x 500W / 6 x 500W / 8x 500W

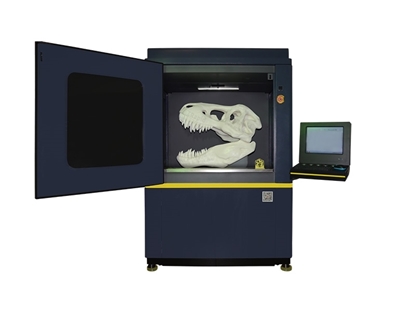

The iSLA660 Ultimate is an SLA 3D Printer ideal for prototyping from ZRapid Technologies.

3D Printing TechnologyStereolithography (SLA)

Laser TypeDiode-pumped solid-state laser Nd:YVO₄

Laser Wavelength354.7nm

Laser Power1000/2000/3000mW

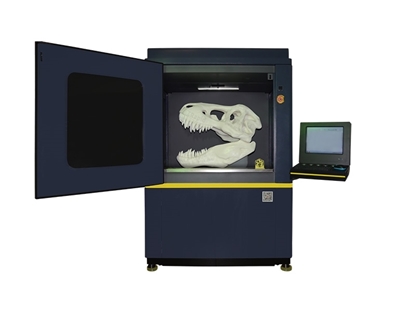

The iSLA880 Ultimate machine is an industrial-grade stereolithography (SLA) printer capable of printing extremely large plastic parts of high accuracy and detail. Ideal for plastic prints of large volumes for prototyping or casting.

3D Printing TechnologyStereolithography (SLA)

Laser TypeDiode-pumped solid-state laser Nd:YVO₄

Laser Wavelength354.7nm

Laser Power1000/2000/3000mW

The iSLA110D Ultimate is an SLA 3D Printer from ZRapid Technologies.

3D Printing TechnologyStereolithography (SLA)

Number of LaserDual Laser

Laser TypeDiode-pumped solid-state laser Nd:YVO₄

Laser Wavelength354.7nm

The iSLA1100 Ultimate is an SLA 3D Printer from ZRapid Technologies.

3D Printing TechnologyStereolithography (SLA)

Number of LaserSole Laser

Laser TypeDiode-pumped solid-state laser Nd:YVO₄

Laser Wavelength354.7nm

- 1

- 2