SLS

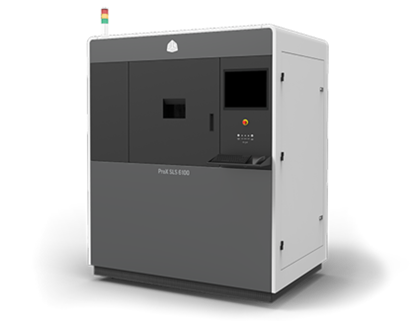

Selective layer sintering (SLS) uses powdered material as input, selectively fusing particles together, layer by layer.

The entire process takes place in a heated pressure chamber. At first a thin layer of powder is wiped over the build plate before a laser melts the particles in the desired spots. The build plate is then lowered and the process repeats.

A huge advantage of SLS is that overhangs and floating objects don’t need support structures. That’s because dense powder surrounds the 3D print until its finished, providing support before the redundant material gets vacuumed off and reused.

With SLS, it’s also possible to print a large quantity of models in one cycle, reducing total printing time.

3D objects printed using SLS are very dense and have very high stability. The surface quality is decent, but can be polished and coated with varnish. The most common material used with SLS is PA (polyamide) which can also be infused with aluminum, glass or carbon fiber, resulting in better wear or chemical resistance. This 3D plastic printing technology is great for spare parts, prototypes and functional components.

- 1

- 2

- 1

- 2